As a business operating in the modern world, it is now more important than ever to become sustainable and minimise our impact on the environment.

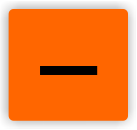

One of the biggest challenges we face as a printing company is ensuring our paper trail has a low carbon footprint and is as environmentally sustainable as possible.

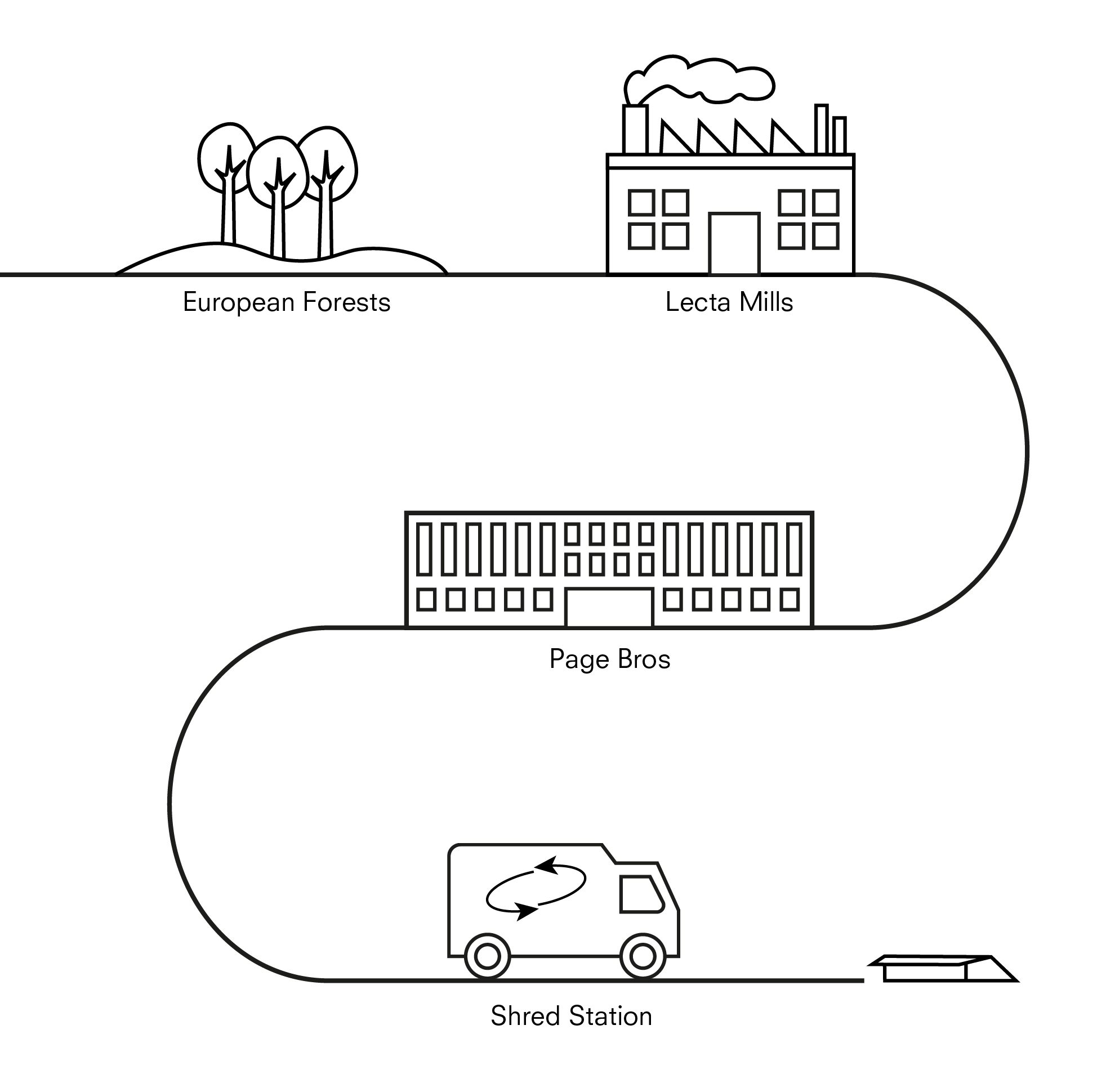

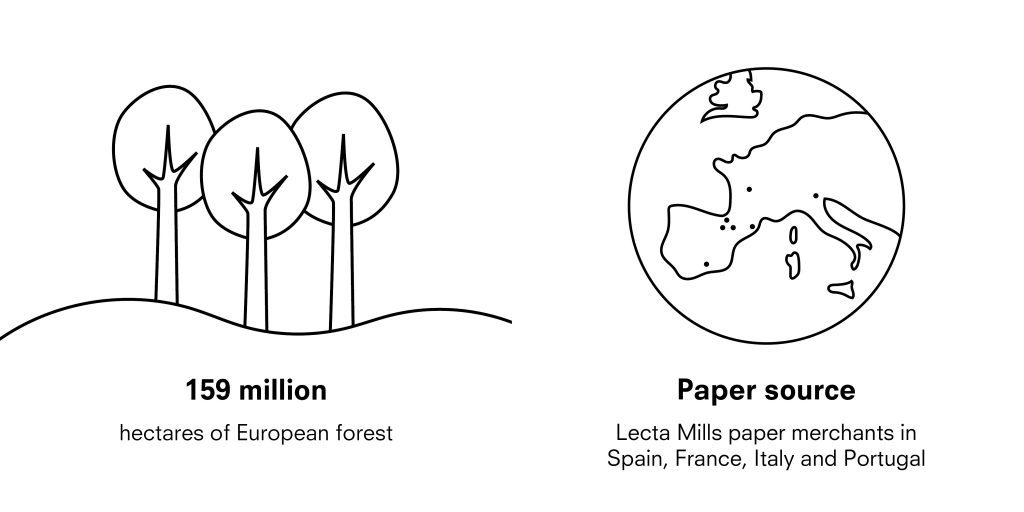

We do this by firstly sourcing much of our raw materials from Lecta Mills, who derive certified pulp from European forests. These forests have grown by almost 10% since 1990 due to ‘plant a tree’ schemes allowing businesses to offset their carbon footprint.

When it comes to printing, most of our inks are vegetable oil-based, plate making is a water-based process. Our five-colour press has a zero-carbon footprint. We annually ensure that our premises, plant, and equipment are serviced to ensure everything is working at optimum efficiency. We have also converted our lighting to energy-efficient LEDs.

After the printing, we need to consider our waste removal. That is why we have partnered with Shred Station, who have a zero waste to landfill policy! We send 100% of our paper to UK processing mills for recycling, and we send our general waste for incineration to make power.

You can read our full green summary here.

Our environmental policy is a keystone of our system for setting objectives for continual improvement and the reduction of our impact on the environment, resource availability and climate change.

Read our full Environmental Policy here and view our sources below.

Lecta Mills

ISO 14001, EMAS standards, ISO 50001, ISO 9001, chain of custody PEFC and FSC

Page Bros

ISO 14001

chain of custody PEFC and FSC

Shred Station

ISO 14001, HMG INFOSEC standards